Victorian Premier's Design Awards 2019: KORE Geosystems - Spector

Victorian Premier's Design Awards 2019:

KORE Geosystems - Spector

Best in Category - Product Design

Congratulations to our award-winning clients KORE Geosystems.

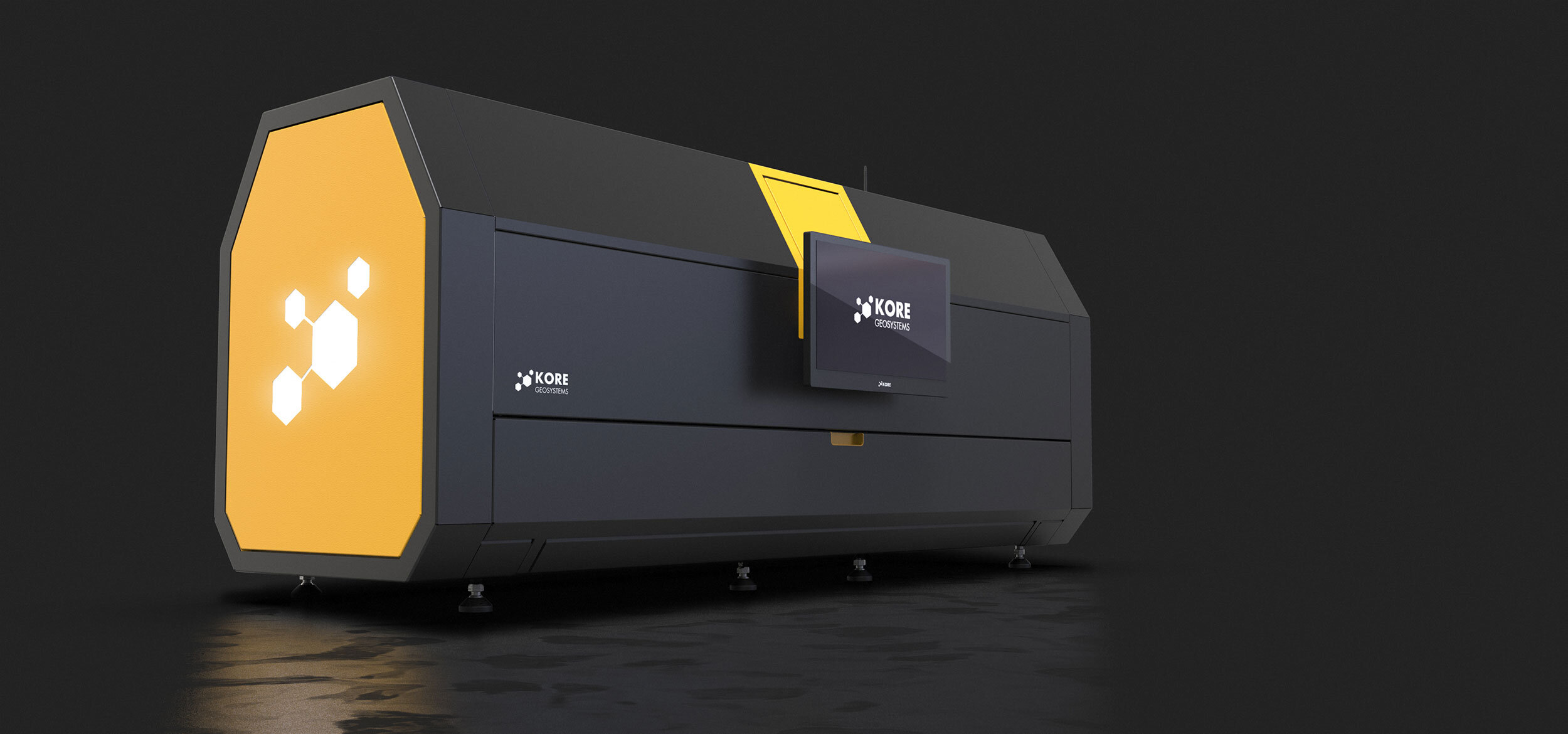

SPECTOR is a fully integrated geological core logging and analysis system that can scan an average of 1,000 metres of core per day. It uses high-resolution imaging and cloud-based AI to improve the speed, consistency and quality of geological data capture — allowing geologists and engineers to spend less time acquiring data and more time interpreting it.

2019 Victoria Premier’s Design Award 2019: Product Design - Best in Category

D+I worked with KORE to design and engineer the hardware component of the SPECTOR solution.

PROJECT TEAM: KORE GEOSYSTEMS | D+I | PROCEPT

Key Features:

Currently geologists are spending half their time entering data instead of analysing core samples. Geologists are highly trained, expensive and in demand and, due to the current core logging process, are not being utilized efficiently. Current core logging techniques employ time-consuming manual photography which can lead to poor quality imaging and core samples deteriorating before they can be analysed. Our challenge was to design and develop an automated core scanning solution that could be used on-location at geological drilling sites around the world, allowing geologists to spend more time analysing samples rather than manually capturing and logging them.

—

We developed a high-resolution instrument built on a robust platform designed to withstand the harsh conditions, dust and temperature variations found on drilling sites. When fully assembled SPECTOR weighs over 400kg, so shipping considerations were integral to the design, from the strengthened forklift points to the robust internal chassis which houses the highly sensitive lighting and optical capture system. The user interface features a large touchscreen display, ergonomically mounted on an articulated arm, for viewing and logging of core scans. Due to the heavy and repetitive loads involved, usability research was undertaken using VR simulations to optimise safety for users.

—

SPECTOR has the potential to have a disruptive impact on mining geology. Its ability to scan an average of 1000 meters of core per day, combined with the cost benefits of having geologists spend more time analysing samples rather than manually capturing and logging them, offers substantial cost benefits to the sector. SPECTOR enables users to employ Artificial Intelligence (via the SPECTOR Geo software and cloud-based AI) to predict the geological attributes of scanned samples, further increasing the cost benefits of the system. The impact of SPECTOR is not limited to cost saving and efficiency, it also improves the consistency and accuracy of core logging, giving businesses the ability to make more informed decisions.

—

The design breaks a cost barrier, making it affordable for deployment to a far greater number of sites. Fully custom heavy duty drawer design, robust articulated 24“ touchscreen, world class optical capture system.

—

The SPECTOR instrument provides high resolution (90um per pixel), consistent images in all lighting and environmental conditions, setup and ready to use in under 5 minutes, requires only limited user training, is fully automated and can image up to 1500m of core per day. Add in the SPECTOR Geo software and Artificial Intelligence and it reduces core logging time by 90%.

There is a significant amount of innovation and use of technology in the SPECTOR solution. The instrument uses high end optics and image processing to provide consistent, calibrated images of any core box, that data is sent to the cloud where Artificial Intelligence automatically identifies the rock, auto depth references, and automatically classifies lithology, alternation and other rock properties for review by a geologist. All this information is accessible through the SPECTOR Geo software.

—

• High-precision linear positioner advances the high-definition camera (housed within an IP67 enclosure) along the length of the imaging area.

• Adjustable core tray backstop to accommodate different sized core trays.

• Drawer locks in the open and closed position to allow for safe loading of core trays onto drawer

• Internet connectivity through Wi-Fi or Ethernet.

• Edge computing allowing image calibration and processing on board to reduce the amount of data transmitted to the cloud.

• Designed to analyse wet and dry core. Instrument has been designed to allow the user to wet the core within the instrument to avoid double handling.

• Onboard diagnostics that allows remote monitoring and remote issue resolution reducing in-field support costs.

• Designed for a 12-month maintenance cycle.

—

SOURCE